SPC Flooring Installation Guide

Once you have all your DECKO SPC boards, skirting, T-moulds, DIY toolkit and other required adhesives for the skirting, you are ready to begin.

Room Preparation:

- Make sure the room you are working on is clear of all furniture and loose objects, making sure you are left with an empty floor. Clean the floor of any removable bumps for example plaster drips. (It is recommended that carpeted rooms have the carpet removed - especially soft carpets - to avoid unwanted vertical movement once flooring is installed.)

- Decide whether you are keeping your existing skirting or replacing or attaching DECKO's skirting over the top. If replacing, remove all existing skirting in the room, before painting your walls.

Laying the SPC boards. First watch this video snippet:

- Decide on the direction you would like the boards to be laid.

- You must leave a gap of 6-8mm next to every single wall (smaller rooms, smaller gaps) to allow for heat expansion. The DECKO DIY Toolkit supplies spacers for this exact purpose. Make sure to have at least two spacers over the length of one board to avoid balancing on just 1 spacer, as this will make install more difficult. (As extra spacers you can use small offcuts of the SPC boards.)

- With the spacers in place, lay the boards in rows, (ie. interlock the ends to make one skinny line of boards from one wall to the other) before continuing with the next row.

- You will have to cut the boards at the walls to fit, but luckily there is an extremely easy way to do this. Mark on the board with a pencil where you want to make the cut, and if you don't have a right angle tool, get another SPC plank and put it on top of the one to be cut so that they are both inline and the top board ends where the cut is to be made (this is so you have a flat surface to cut against).

- Take your Stanley knife and cut the top of the board across the cutline. The objective is to just cut into the top film layer so when you flip over the board and flex it downward, the board will break at that point. Then simply cut the underlay EVA foam to fully separate the two sides.

- At the start of each new row, make sure the boards' joints are staggered with respect to the previous row, ie. 1st row start with a full board, the 2nd row start with a half board, the 3rd row start with a full board, the next a half board and so on. (You may wish to employ a more intricate pattern)

- Once you reach the other side of the room, you may have to make cuts longways to fit the boards in. Even on this side of the room, make sure to leave the 6-8mm space.

Around Door Frames

For a clean, professional finish around door frames, we recommend undercutting the jambs (common practice for floating flooring) rather than cutting complex board shapes.

Use a scrap piece of SPC flooring as a height guide for your flush saw or multi-tool. Undercut the door jamb and architrave, then slide the plank underneath for a clean, seamless fit. Always leave a 3–5mm expansion gap hidden beneath the frame.

For any clarification or query, please contact us with photos or diagrams for clarification

Install the Skirting. First watch this video snippet:

- The first step is to remove all the spacers from between the wall and SPC planks.

- Start on the corner of the room where the factory pre cut skirting will be advantageous in joining with the other direction of skirting. (These factory cut 45 degree skirting joins offer a larger surface area to be glued together on, therefore making them stronger, as well as hiding the joins better.)

- Use the plastic specific superglue to glue only the skirting pieces together in a line along the wall segment. *Make sure to use a mat or news papers to protect the already laid SPC boards from glue drips etc. Adhere to all instructions and warnings on the superglue bottle. Make sure to immediately wipe off any excess glue that gets squeezed out between the joins to not allow them to solidify using a piece of paper or throw away rag.*

- Cut the last piece to the right length and angle for your wall segment (this is easily done using the Mitre Box included in the DIY toolkit).

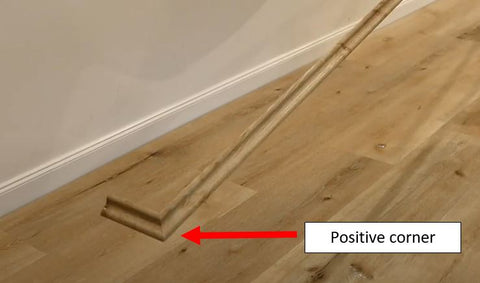

- When laying skirting around a positive (exterior) corner, it is best to first glue the skirting pieces together at the corner, then as a unit be glued to the wall with the adhesive sealant as seen in the video. This will make the most attractive corner joint possible.

- Once all the skirtings to a wall segment have been glued together in a straight line and the glue has set enough, apply an even bead of adhesive sealant to the wall where the lower half of the height of the skirting will be in contact with it. The easiest way to do this is as seen in the video, to use an offcut skirting piece as a guide for the nozzle of the caulk gun and sliding it backwards steadily as the adhesive is applied.

- After this, press the entire skirting in place against the adhesive, and use the duct tape provided to tape the skirting to the SPC boards to keep them in place. Aim for 1 place to be taped for each 1220mm long skirting piece. (Careful not to tape to the wall as the paint will almost certainly come off with the duct tape.)

- Wait 24 hours for the adhesive to properly set before removing the duct tape.

- Repeat this process for each wall section in the room.

For any clarification or query, please contact us with photos or diagrams for clarification

Tips:

- For making the cut on the last board in a row, spin the full board 180 degrees around so that it is still facing up but it wouldn't interlock, then place the end of the board against the spacer at the wall and mark the cut where the board overlaps the previous board. This will ensure the perfect size end cut every time.

- If you need to hit the side of the board with a mallet for easier interlocking or any other reason, do not hit directly on the good board's clipping system as it can get damaged, instead get an offcut piece of a board, interlock that into the board in question and hit the side of the offcut to safely transfer the force into the good board.

- If a wall is not 90 degrees perpendicular to the other walls, after cutting the first SPC board against this wall, use the offcut as a template for all the subsequent cuts at this wall.

T-moulds

Our colour-matched T-moulds provide a seamless transition between rooms or flooring directions, making them ideal for bridging different floor types or starting a new laying pattern.

Installation is simple: leave a 10–30mm gap between the two flooring sections, apply a continuous bead of polyurethane or silicone-based adhesive onto the floor in the gap, and press the T-mould into place with the base of the “T” seated firmly in the adhesive. The T-mould can be installed at an angle, as shown below, to accommodate height differences between adjoining floor surfaces - such as carpet meeting DECKO SPC flooring.

Bathroom-Specific Considerations

SPC flooring is 100% waterproof with watertight joints, making it an excellent choice for bathrooms. However, additional waterproofing steps are necessary to ensure long-term durability and prevent water damage beneath the flooring.

1. Pre-Installation Waterproofing

Before installing SPC flooring, the bathroom must be properly waterproofed, just as you would if installing tiles. This includes:

- Applying a waterproof membrane to the subfloor.

- Ensuring all wall and floor junctions are sealed.

-

Waterproofing around drains and any wet areas as per local building regulations.

2. Edge Waterproofing with Silicone

To prevent water from seeping underneath the boards:

- Apply a continuous bead of waterproof silicone sealant along all edges where the SPC meets walls, cabinets, or other fixed objects.

- Ensure the silicone fully seals the perimeter, acting as a barrier to moisture.

3. Sealing Around Drains

Drains are key areas where water can penetrate beneath the flooring. To mitigate this:

- Create a ‘bed’ of waterproof silicone around the drain area.

- Lay the SPC boards directly onto this silicone bed to form a watertight seal.

4. Proper Board Connection

To maintain the waterproof integrity of the flooring:

- Ensure all SPC boards are properly interlocked.

- Check each joint carefully to confirm that the click-lock system is fully engaged.

- Avoid forcing boards together in a way that might damage the locking mechanism.

By following these extra considerations, you can achieve a fully waterproof SPC flooring installation in your bathroom, ensuring longevity and protection against moisture-related issues.